To clearly identify the operational contest, we have considered data inventory of all the agricultural phases of grape production related to a Functional Unit (FU) corresponding to 1 kg of grape.

Preliminary data to be used as reference baseline, have been already collected by DIBAF with preparatory works on an experimental vineyard in Italy in order to estimate the FU of an area of 1 hectare (representing the average area for vineyards in EU) and characterized by a standard production of 10-15 tons of grape resulting from 5000-6000 vines and with a standard agronomic and phytosanitary management of 10 treatments per year among fungicide and insecticide.

All the main viticulture input required for 1 hectare of vineyard (including water, land occupation, electricity, diesel, phytosanitary products, fertilizers) and main outputs (including emissions to air from diesel combustion and from pesticides, and emissions to water and soil) have been described on a scientific paper under publication that will be used as reference to compile the Key Impact Indicators table in the full proposal.

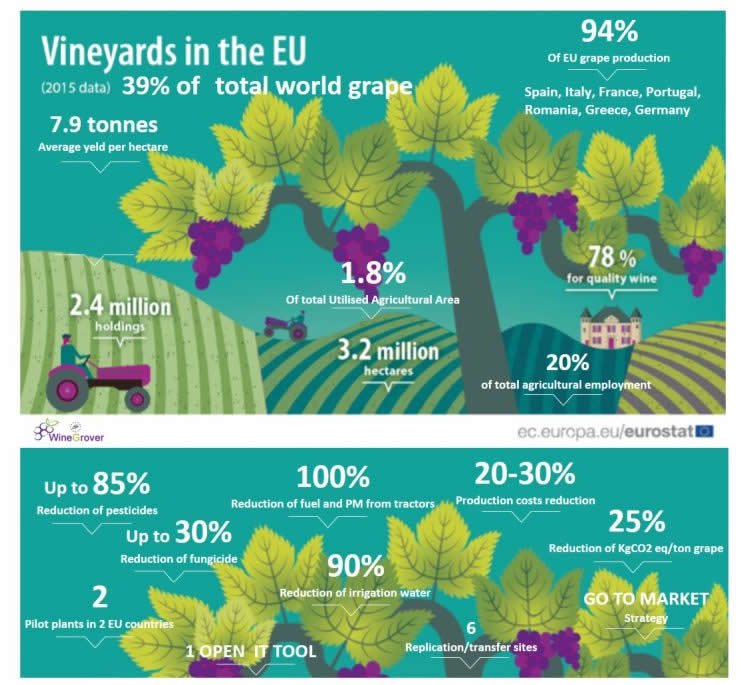

Quantified expected results and impacts will be:

-Reduction of the use of pesticides up to 85% and of the use of fungicide up to 30% when compared to conventional vineyard disease management.

-To contribute to the implementation of UNECE Code of Good Practice limiting ammonia from the use of mineral fertilizers. We estimate a reduction up to 2kg N/ha of Nitrogen fertilizers with a potential reduction up to 97% of N applied in vineyards and consequently NH3 emissions and risk of eutrophication.

-100% reduction on the use of diesel fuel correlated to the distance travelled by tractors for the cultivation of vineyard, pesticide application, soil and canopy management intervention with an estimated 0.15gr/year PM and VOCs reduction per FU resulting from the use of the electric rover instead of the tractor. Previous results shown that external inputs such as 234 g Diesel fuel and 4 g of Lubricating oil are required per FU.

-To reduce the water consumption for irrigation up to 90% thanks to precision drip foliarirrigation compared to flood irrigation.

-To lower production costs between 20 and 30% compared to traditional system.

-To plan the replication and transference of the results to 6 vineyards of other regions in Europe during the 3 years after the end of the project.

-To foster the deployment of the project at local and EU levels through targeted dissemination actions toward relevant stakeholders and general public promoting networking with grape producers and other farmers since the system could be applied to other crops.

-To enter the PA market with a new competitive product promoting and exporting EU technology also in countries devoted to intensive agriculture establishing a leadership position early in vineyards and then scale to other crops (olive groves and kiwis).

-To contribute to climate targets with a reduction of 25% kgCO2eq/ton grape.